1.2MM - 3MM Q195-235 Z C Purlin Forming Machine With 17 Forming

Roller

Equipment Description

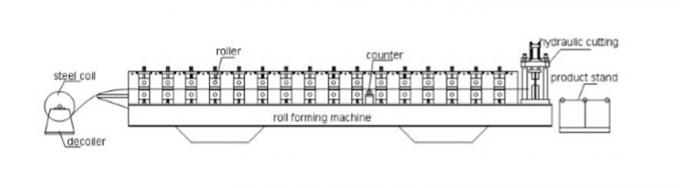

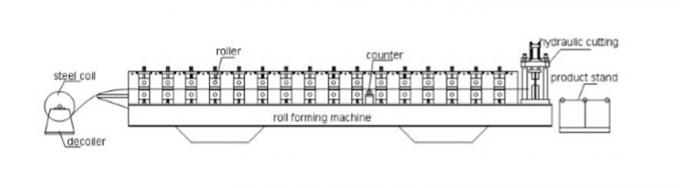

1. The Chart of Process flow

Manual de-coiler --- Electric Feeding --- Servo motor feeding

----oll Forming Machine------Computer Control Cabinet---Automatic

cutting Mechanism ---Run-out Tables

2. The equipment including

| Roll forming machine | 1 set |

| Hydraulic cutter | 1 set |

| Electrical control system | 1 set |

| Hydraulic system | 1 set |

| Normal run out table | 3 PC 1m*1m |

| Manual de-coiler | 1 set Max. loading 5 T |

3 Technical specification and details

(1) Hydraulic Ue-coiler

Un-power: manual de-coiler; Max. Capacity: 7T

Suit for coil inner diameter: 508mm, suitable coil Max. out

diameter: 1000mm

Manual power expands the coil inner surface.

(2) Roll forming machine

| Description |

| Product Name | C/Z Purlin Rool Forming Machine |

| Machine Size | 11000mm*1500mm*1000mm(Actual size based) |

| Machine Weight | About 10 T |

| Frame Materials | 350H steel |

| Middle plate thickness | 14mm |

| Forming Shaft | Diameter | 80mm |

| Material | 40Cr Heat treatment |

| Forming roller | Gr15Bearing steel, whole quenching, HRC58 |

| Cutting System | Hydraulic Cutting |

| Drive mode | 6 points sprocket, chain / 1 inch sprocket, chain |

| Main Engine power | 18.5 KW with cycloidal reducer |

| Fast moving motor power | 2.2kw/set (A total of one) |

| Forming Rows | 18 rows |

| Forming Speed | 10-16m/min |

| Pressing Thickness | 1.5-3mm |

| Coil material | Galvanized Coils: Q195-Q235 |

| Punching die, cutting machine blade material | High quality Cr12MoV |

| Punching, cutting machine cylinder number | 2 |

| Hydraulic station power | 7.5kw |

| Hydraulic pressure | Max30Mp |

| Electric Control System | International, domestic brands, mainly by Panasonic, Yaskawa, OMRON

brand |

| Transducer | SIEMENS |

| Encoder | OMRON |

Equipment for Reference:

(3) Hydraulic Cutting

1) Adopts post cutting, Stop to cut;

2) The cutting blade material is Cr12 with quenched treatment.

3) Adopts welded frame for good rigidity.

4) Cutting frame has been heat treatment to avoid final product

deformation. cutting length tolerance ±2mm.

5) The power of cutting is provided by hydraulic station.

6) The final product can be cut as per set length in PLC

controller, and the length is automatically measured by encoder.

When final product reaches the set length, machine will stop to cut

the Product automatically. Finish this action, machine will run

again continuously.

(4) Hydraulic station

1) It supplies the power for the hydraulic cutter.

2) All hydraulic accessories are all use Chinese famous brand

products.

4) Hydraulic motor power: 3KW

(5) PLC Control System

1) This system uses Delta PLC to control the all working actions.

Production quantity and each piece length will be automatically

measured. It is convenient to control the roll forming machine.

2) Delta converter adjusts speed technology, realize the automatic

production.

3) Text screen is input and cancelled the working data.

4) Friendly man-machine interface system can be set batches to the

work piece, length, quantity, etc.

5) Encoder count, having function of count and measuring length.

6) Suitable power voltage: 380V/50HZ/3Phase (can de designed

according to buyer’s requirement)

(6) Product Rack (un-powered)

1) They are used to put the final product when product coming out

from cutting device.

2) Two pieces, each piece length is 1m, total length is 3 meters.

3) Collect the final product and final products are convenient to

be stacked by workers.