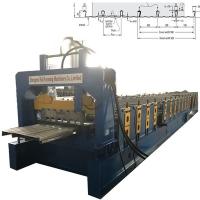

RFM Cold Rolling Forming Machinery

we can manufacture contains: roofing sheet machine, CZ purlin

machine, light steel gauge machine, metal embossing machine, door

system forming machine, ceiling system machine, pipe welding

machine, slitting and cut to length machines, rack system machines,

floor decking machine, stone coated steel roofing sheet machine as

so on. The company has passed ISO9001 quality control system

certification, European CE safety certification, North American CAS

electric certification, and has instill the concept “time is money,

quality is life, customer is the king” into the mind of every

employees. We strictly control quality while improving production

efficiency and shortening delivery time. All the machines produced

by us need full line test before leaving the factory, we never send

problematic equipment to customers. We have full experience of

export and know well about the different needs of customers from

both developing countries and developed countries, we provided many

satisfactory machine proposals to customers in the past years.

Nowadays our machines have already been exported to more than 150

countries and we established long-term and stable cooperative

relationship with our clients.