Metal floor decking rolling forming machine for Russian

Metal floor decking rolling forming machine for Russian is designed

to make the metal decking sheets in batch fully automatically. Here

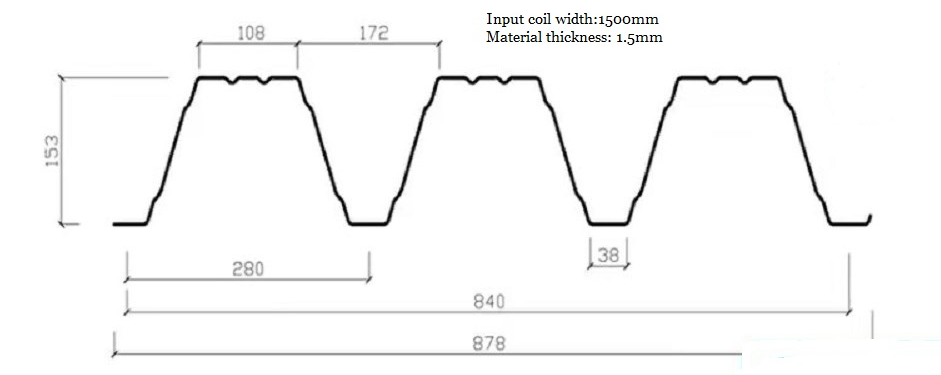

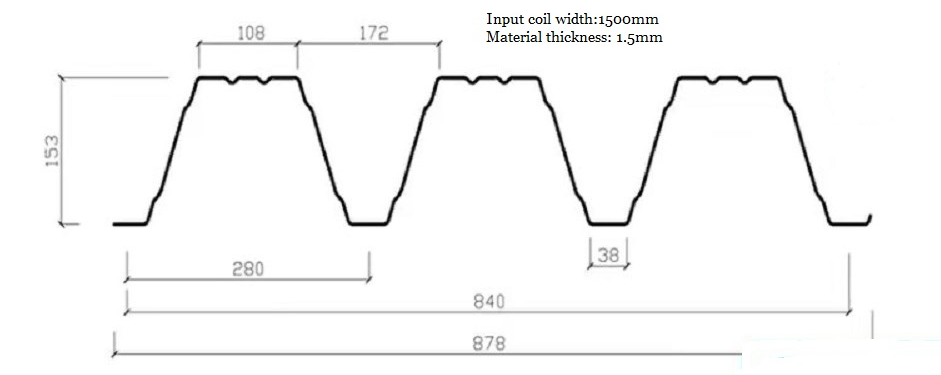

we check the following drawing profile:

This metal decking profile we use 1500mm input coil width and the

material thickness Max customer requirements is 1.5mm. As to the

installation width is 840mm.

Wave height: 153mm

Wave width: 108mm

Wave distance: 172mm

Metal floor decking rolling forming machine for Russian

Here are the machine parameters for your reference:

Rolling shaft

| Shaft Material: 45# steel, surface hard chromium plating. |

| Shaft diameter: 110 mm |

| Tampering treatment, prevent deformed and improve the hardness |

Roller

| Roller material: Gcr12mov |

| Chromed treatment (Cr thickness:0.05 mm), anti-corrosion,Increase

hardness, ensure the precision and good abrasion performance |

Rolling station

| 48 stations |

| Includes one set embossing rolling station, embossing roller shaft

120mm, with support bracket |

| Work speed :0-15 m/min |

| Machine structure | Middle plate welded structure |

| Steel plate thickness: 20mm |

machine basic frame | 400# H steel welded with diagonal bracing inside |

| The diagonal bracing can ensure the full set basic frame in the

same horizontal level to prevent the sheet shift left or right.

Meanwhile it can make sure the machine in a high stability when

working. . |

| Bearing | Chinese famous brand Harbin |

| Work power | 22 kw *3 customize according customer requirement |

| Brand: China famous brand |

The difficulty of this machine rolling forming:

1. The material thickness to 1.5mm, so we have to use 110mm shaft

diameter.

2. The profile height to 153mm, that means the roller outside

diameter to 300mm around, so super big machine.

3. The machine takes 48 roller stations to do the rolling forming.

4. The machine power to 22KW with 3 motors.

5. By those reason, this machine is not cheap and price is higher

than others. And the machine weight maybe to 40 Ton.

6. As to the loading and installation, we will design it into two

parts and then you can do the connection by bolt and nuts when you

need machine working.

1. As to the profile is too big, in order to make the wave more

straight, at the side wave we add more ribs. Or you can add some

embossing pattern. For the shearing part, we use the 3 pieces

cutting blades shearing to make sure the shape perfect good.

- Add a pair of gears to the first row of rollers (embossing rollers)

to make the upper and lower rollers rotate at the same time, making

it easier for the steel coil to enter the forming machine.

- Add clutch device is installed for the embossing roller, which can

connect or cut off its driving force. It is easier to connect when

feeding, and disconnect the power after the coil enter into roll

former, so as to avoid the coil curve caused by the inconsistent

speed between the embossing roller and other forming rollers.

- As to the decoiler part, you can choose to the manual one or

hydraulic one. Normally for the heavy duty type, we use the 15 ton

automatic hydraulic decoiler with the loading car.

For more information, please contact us at any time.