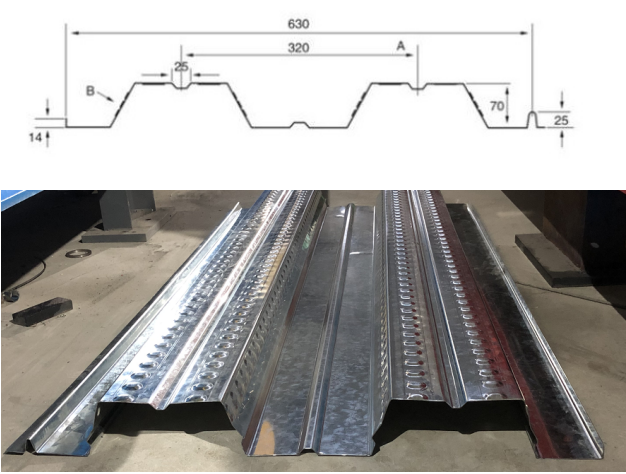

Steel Floor Deck Roll Forming Machine for Jordan

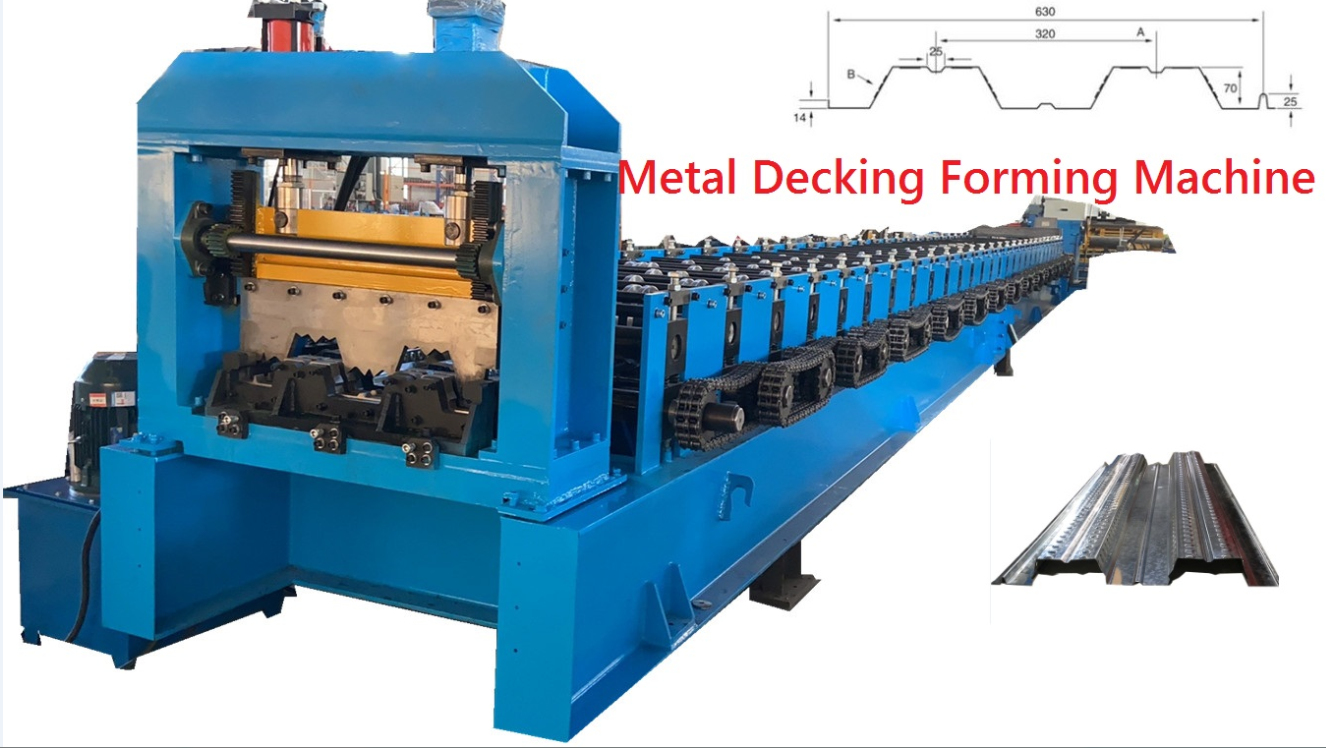

Steel Floor Deck Roll Forming Machine is designed to make the metal

decking profiles in batch fully automatically. Here we take one

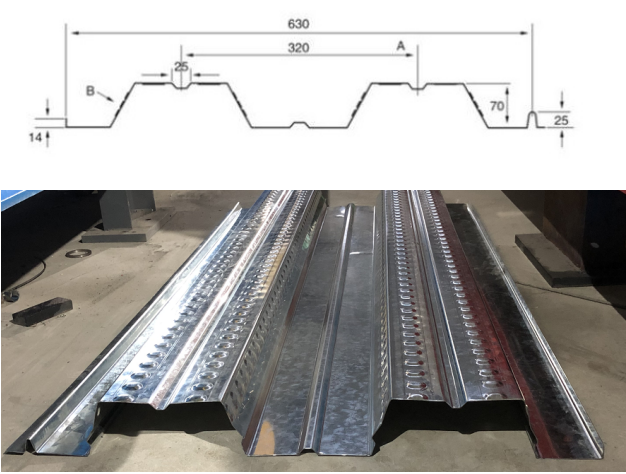

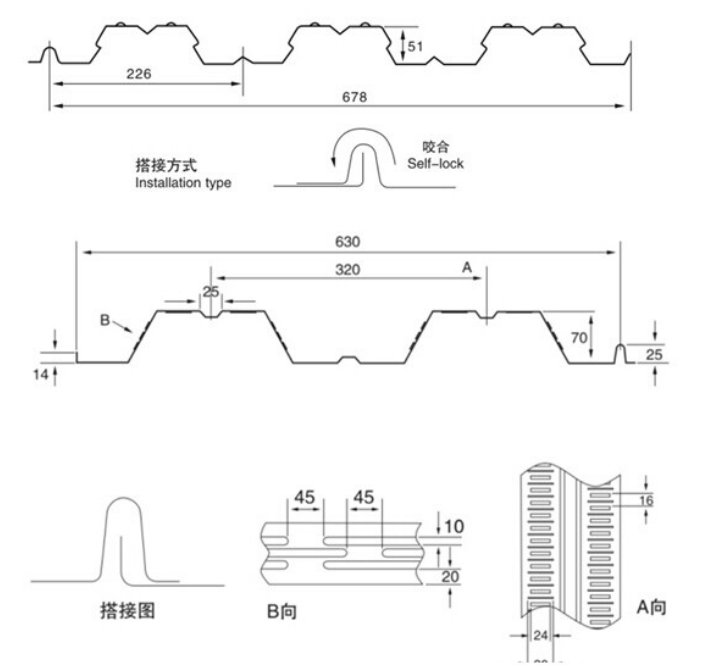

steel decking machine we made for Jordan. This profile valid width

is 630 and the wave height is 70mm.

Main Feature of Steel Floor Deck Roll Forming Machine for Jordan:

1. Metal deck plate adapt to the requirements of the rapid

construction of the main steel structure, can provide a firm

working platform in a short time, and can be used to lay multiple

floors of pressed steel plate, layered concrete slab water

construction.

2. As the tensile reinforcement of concrete floor, the metal deck

plate improves the stiffness of the floor and saves the amount of

reinforcement and concrete.

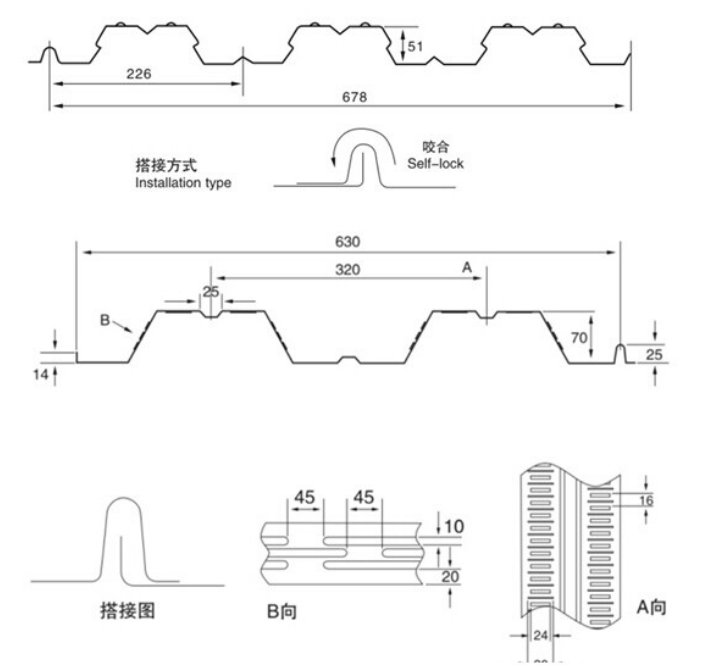

3. Pressure plate surface has embossing between the metal deck

plate and concrete to produce the maximum binding force, so that

the two into a whole. Metal deck floor usually has stiffening rib,

so that the floor bearing plate system has a high bearing capacity.

4. Under cantilever condition, metal deck plate is only used as

permanent template. The length of the cantilever can be determined

according to the section characteristics of the bearing plate. In

order to prevent the crack of the cantilever plate, negative

reinforcement should be provided at the support according to the

design of the structural engineer.

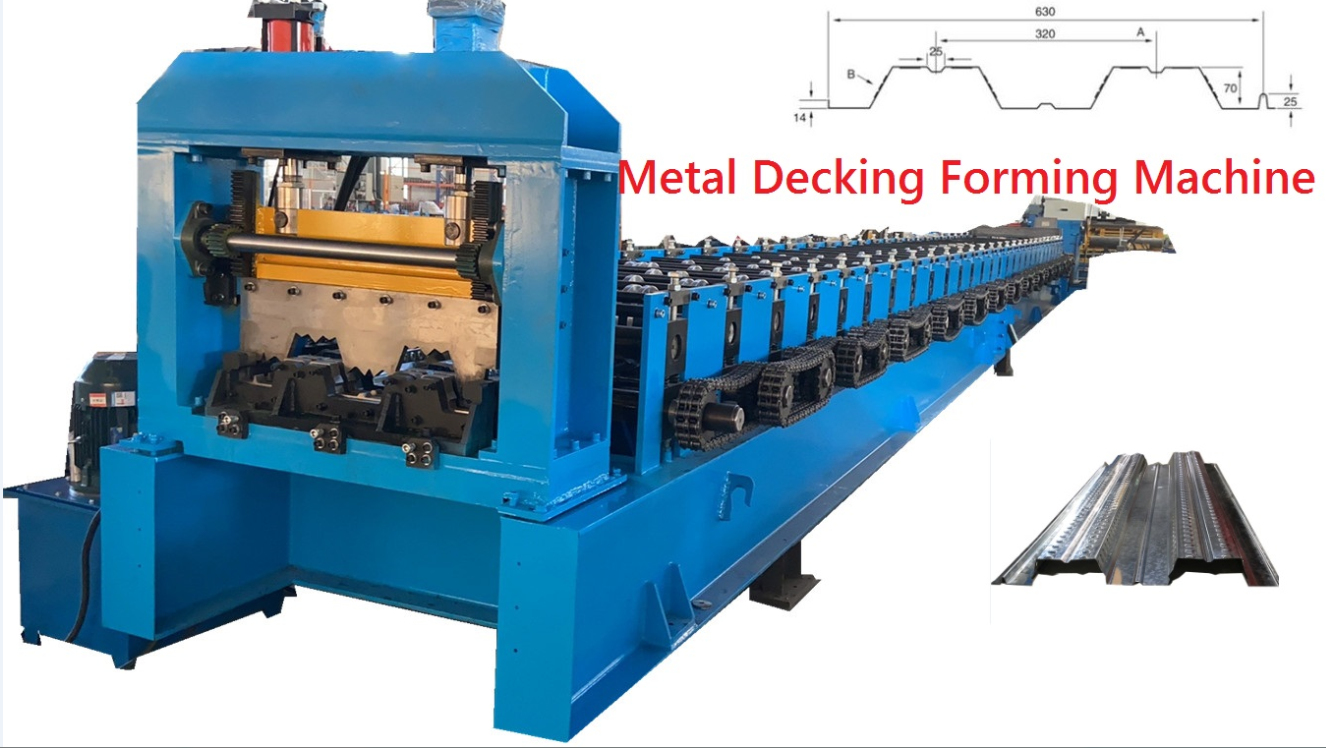

Main Parameters of Steel Floor Deck Roll Forming Machine for Jordan;

| Forming steps | 26 roller stations |

| Rolling method: for rolling methods, we use the separated molds

rolling forming. |

| Shaft diameter | 90mm, the embossing roller=120mm |

| Design type | Middle plate welded |

| Machine frame thickness | 20mm |

| Machine frame | 400# H steel welded |

roller material

| 45# steel, surface hard chromium plating. |

| shaft material | 45# steel adjusting the density |

| Work speed including shearing | 8-12m/min |

| Transport | By chains of 1.25mm |

Power of main machine

| 11kw x2 two motors to give the power more evenly to the machine |

1. We use the double chain for big power and long time to use.

2. Strong shaft with keynote.

3. Leveling with gear outside and with the protection rollers.120mm strong embossing roller with protection shaft.

Where to use the Steel Floor Deck:

More profiles of metal decking for your reference:

Here is the Steel Floor Deck Roll Forming Machine for Jordan testing video for

your reference: