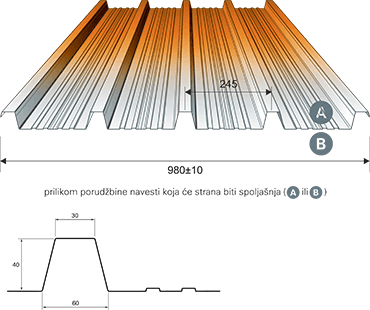

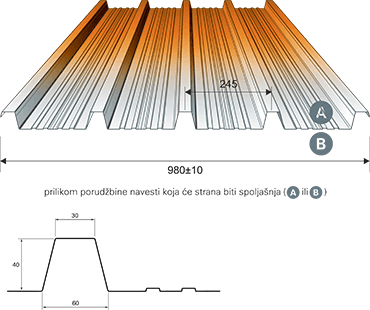

Roofing Sheets Used in House Construction Tr40 Metal Roofing Sheets Machine

Roofing Sheets Used in House Construction Tr40 Metal Roofing Sheets

Machine is designed to make the roofing sheet in batch fully

automatically. Profile is intended for covering walls in industrial

objects. It is made of galvanized and steel galvanizeg plasticized

sheet metal. According to tolerance EN 10143. Here is one drawing

profile for your reference:

If you want to add the felt or filming for better usage, no matter

for the coil and the machine, we can make for you.

Roof profiled sheet TR-60 is also quite popular. Compared with Tr40, TR60 has more wave

height. Profile intended for roof covering of objects with small

slopes above 4°.It is made of galvanized plasticized sheet metal.

For House Construction Tr40 & Tr60 Metal Roofing Sheets machine

design, we have two options: One you can design them to single

layer machine, two you can design them to double layer machines.

Here we will take the double layer machine design for your

reference:

| The machine is composed by the following elements |

| NO. | Item name | Quantity |

| 1 | 7 Ton hydraulic decoiler | 1 set |

| 2 | Leveling beach with manual cutting | 1 set |

| 3 | Main formingmachine of double layer of Simens motor | 1 set |

| 4 | PLC control system using Mitsubishi | 1 set |

| 6 | Hydraulic pump station with cooling system | 1 set |

| 7 | Output table | 1 set |

| 8 | Working speed | 25min/min |

| Entry Beach(Picture 2) |

| Usage | Put the raw material (steel plate) through the beach to manufacture

and process, it can guarantee that the products are neat, parallel

and everything is uniformity. Please refer to the equipment

regulation to know the function of locate board. Meanwhile with two rollers stations of rubber to make sure the coil

feeding direction and note go swing. |

|

| At the first two roller station, put the gear outside to make sure

more powerful coil feeding. |

|

| Main Roll Forming System(picture 3 ) |

| Usage | In order to keep the product shape and precision, adopts welded

sheet structure, motor reducer drive, chain transmission, roller

was chromed which can keep the molding plate surface smooth and not

easy to be marked when it is being stamped. |

| MACHINE | About8500х1650х1500mm |

| Weight of main part | About 10.5 T |

| Voltage | 380V/50HZ3Phase (as customer’s request) |

| Roller fixer | Middle plate welded |

| Frame | 400 H steel welded |

| Frame thickness | 20mm |

| Drive mode | Chain 1.25 |

| Material of rollers | 45# steel, queening and then surface hard chromium plating. |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ80mm |

| Number of rollers | First layer=20 rollers station Second layer=24r roller station |

| Note as to the first layer, the height just 18mm no need to add

gear. And to the second layer, as the wave height is 35mm, and

there are 24 roller station, so there will be 20 roller station

with the bearing, and then the Max mold size diameter is around

230mm. |

| Main power | 15 kw, the motor brand is Siemens |

| Note : the machine design using the separated molding rolling

forming and before shearing there are two more roller station to

rolling whole mold to make sure the shape beautiful. |

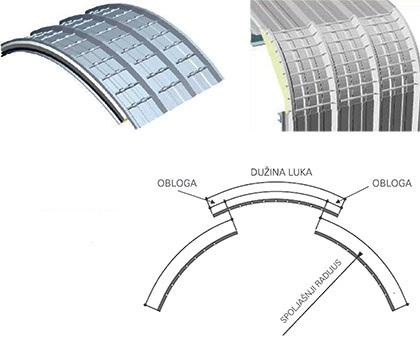

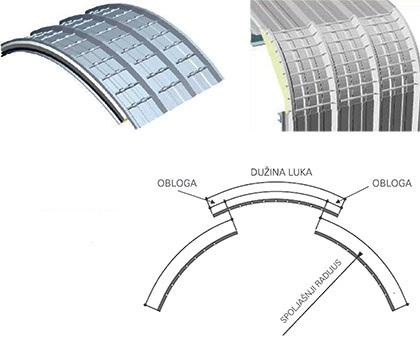

Arched profiled sheets TR-40

Arched bend profiled sheets TR-40 is used for covering arched

roofs.

It is designed to improve roof appearance, facade, arches and other

detail on objects.

Arch bending of profiled sheet is done at the object according to

projected radios.

Arched profiled sheets TR-40 hydraulic bending machine could be designed like this:

For those machines, if you want to know more information, please

contact us at any time.