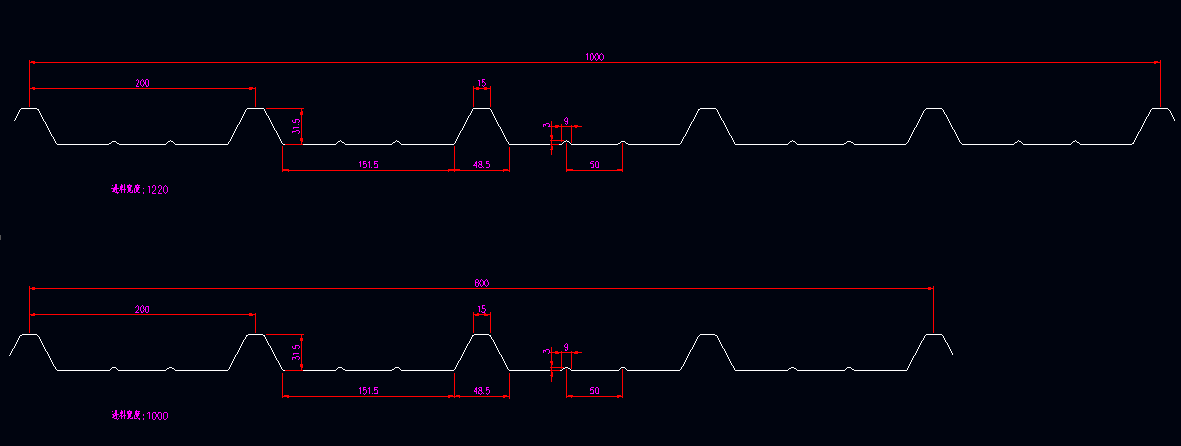

Metal roofing sheet rolling forming machine for Saudi Arabia

Metal roofing sheet rolling forming machine for Saudi Arabia is

designed for making the roofing sheets for Saudi Arabia. This

machine we specially design for Saudi Arabia market with the

following drawing profile, which is quite popular now.

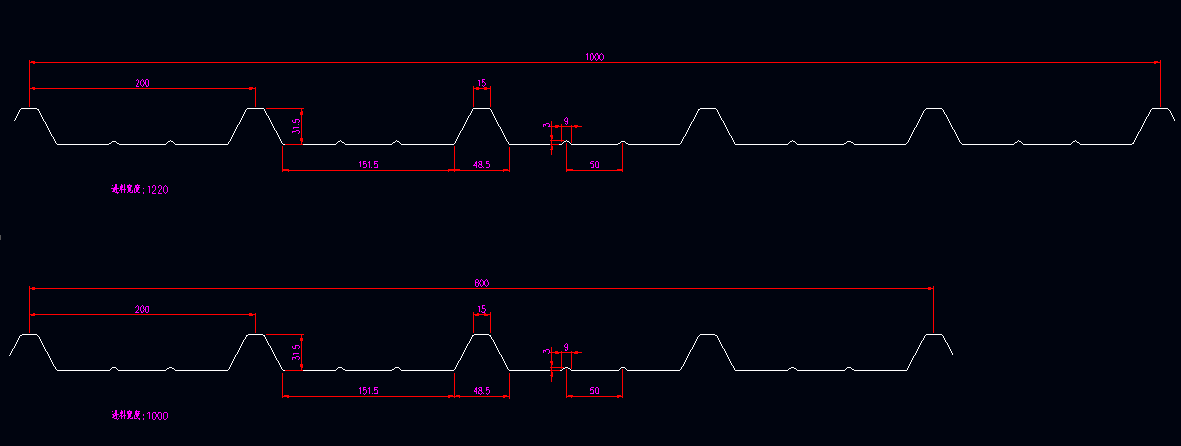

Note: for this profile, it supports both input coil width: 1220mm

and 1000mm, so both two types input coil width could be used by

this machine. When using the input coil width 1220, the effective

width is 1000mm. When the input coil width is 1000mm, the effective

width is 800mm. By this way, simple adjusting the input coil width

and then you can make two types roofing sheets.

| Metal roofing sheet rolling forming machine Parameters |

Feeding device | One set guiding roller |

| Steel plate welded platform to carry the sheet and feed into roll

forming system |

| Feeding width is adjustable with the handle wheels |

Rolling shaft | Shaft material:45# STEEL |

| Shaft diameter: 75 mm |

| Tempering treatment to prevent deformed and improve hardness |

Roller | 45# steel |

| Chromed treatment, improve the hardness and prevent abrasion, anti

corrosion increase of service life |

| Rolling station | 19 rolling stations |

| Work speed | 25m/min {4 pieces per minute (6m per piece)} |

| Machine structure | Steel plate welded structure |

| Machine basic frame | 500# H steel welded |

| Work power | 7.5 kw |

| Rolling spacer | Anti rusty treatment |

| Pull rod | Anti rusty treatment |

| Transmission | By Chains with cover |

| Noted: please fill the lube in case the chains getting dry |

1. The hand wheels on both sides can fine tune the width. Keep the

coil straighten by sliding the coil between the slots on both sides

when feeding. This mechanism is equip with bearings inside for

smooth feeding.

- Equip with stainless steel solid shaft with bearing on both sides

for smooth feeding to the main forming stations. The two roles of

orange plastic rollers supports the coil to the machine and this

will prevent damaging the coil.

- As to the rolling forming part, we design it using the separated

rolling forming that means each roller station only rolling one or

two waves and then it will not damage the surface of the coil.

3. We use high quality ball bearings for our rollers and shafts to ensure the machine run smoothly and

efficiently. All main forming rollers are chrome plated with 3mm coating to increase hardness, anti-rust and longevity. Rollers, spacers

and shafts are mark with numbers for easy maintenance in the future.

1.This machine equip with hydraulic cutting. It is fully controlled

by PLC system.

2. Equip with double pillar design makes the cutting procedure more

precise.

3.Cutting blade uses high quality Gcr12Mov Chromed and quenched

HRC58-62 material for your production demand.

4.Tolerance: 3m ±1mm

Here is the Metal roofing sheet rolling forming machine for Saudi

Arabia working video for your reference: