Composite metal floor decking rolling forming machine

Composite metal floor decking rolling forming machine is designed

to make the metal decking sheet in batch fully automatically .

Combined trapezoidal and re- entrant 80mm composite profile with

long span capability. Versatile. Combined profile allows easy

service attachment, with trapezoidal spanning ability.

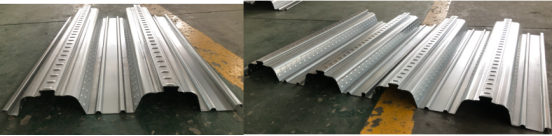

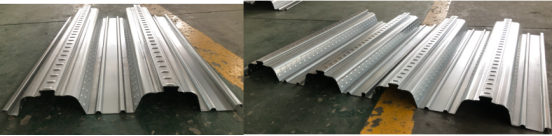

Here will show you some popular designs for your reference:

They are different in the height and embossing types, so those data

could be customized according to the input coil width and customer

requirements. Here are some decking pictures with single profile

and overlapping for your reference:

Composite metal floor decking rolling forming machine

Frame design: keep the molding plate surface smooth and not easy to

be marked when it is being stamped.

Length of the main part: about 25000 х1650 х1500

Weight of main part: 15300kg

Voltage : Customize

Roller fixer : middle plate of thickness 28mm

Frame : 400 H steel welded

Drive mode: double chain with the chain adjuster for lose and tight

degree.

Material of rollers:Gcr15, surface hard chromium plating.

Material of shafts: 45# steel and adjusting the hardness.

Diameter of shafts: φ 90mm embossing rollers are about 120mm.

Number of rollers : 36 rollers

Main power: 15*2kw

Shearing Mechanism

Feature:Ensure stability,precision and cutting speed

Function : Automatic cutting controlled by PLC

It adopts the hydraulic drive and automatic location to decide the

dimension and cut the target products.

Material of blades:Cr12 quenched

Power supply : hydraulic power

Components:It contains one set of blade , one hydraulic tank and

one cutter machine.

You can choose to add the before shearing or not . If you wan to

add, you can cut at any length and reduce the wastage of the coil

in the machine.

This metal decking profile is not easy to make, as it needs lots of

side rollers to shape the dovetail.

About the overlap effect.

| Item | Parameter detail |

| Processing Material | GI and PPGI |

| Material thickness | 0.25-0.8mm |

| Machine frame | 360#H steel, Adopt diagonal line welding, leveling instrument

measurement to make sure the final frame is high-precision |

| Machine siding panel | | plate type | Pillar type(option) | | | | Plate thickness:20mm | Pillar thickness:30mm | | Painting:normal painting | painting:Chroming |

|

| Forming stations | 20-38 stations(according to the profiles) |

| Machine rollers | high grade No.45 forged steel,plated hard chroming with thickness

0.05mm

Processing way:cutting--drilling--CNC lathing--quenching--CNC

lathing--chroming |

| Machine Shaft | φ80-90mm high garde No.45 steel after treatment, |

| Machine spacers | CNC lathing in high-precision |

| Machine bearings | China Haerbin bearing or SKF international bearing(option) |

| Driving system | 2 inch chain or gear box(option) |

| Machine power | 15kw-22kw(according to the profiles) |

| Machine working speed | 8-12m/min or 10-30m/min(option) |

| Machine adjust type | After machine installation, we will test it ourselves, compare with

the profile drawing, the difference is controlled in 0.5mm |

Cutting

| Type | bearing sliding type |

| Blade material | Cr12mov quenching and grinding |

| Frame processing | the whole bottom frame is grinding for high-precision |

| Blade processing | wire-electrode cutting, but the upper balde can not be straight.

this is technology |

| Working | Hydraulic type |

Stacker

| Type | Manual |

Auto(option) |

| Length | 1.5m-2m | 6m or 12m |

PLC

| Main item | Parameter detail |

| PLC | Delta(standard) or according to your request |

| Inverter | China brand(standard) or according to your request |

| Touch screen | Mcgs(standard) or according to your request |

| Encoder | China brand(standard) or according to your request |

| Voltage/HZ/Phase | 380v/50-60hz/3phase |

Hydraulic pump

| Main Item | Parameter detail |

| Motor | 3kw China brand or according to your request |

| Pump | China brand or according to your request |

| Solenoid valve | China brand or according to your request |

| Cooling system | Cooling fan |

Floor Galvanized Steel Decking Panel Roll Forming Machine PLC

Control System

Machine components

| No. | Name | Qty |

| 1. | De-coiler | 1 Set |

| 2. | Roll Forming Machine | 1 Set |

| 3. | Hydraulic Cutting Device | 1 Set |

| 4. | PLC Control Box | 1 Set |

| 5. | Hydraulic Pump | 1 Set |

| 6. | Output table | 1 Set |