High Quality Rolling Storage Rack Machine

Automatic Shelving and Storage Racking Roll Forming Machine can

produce the profile with following different size, with servo

feeding device and punching bed.. Special sizes of the profile can

be designed in our company.

Automatic Shelving and Storage Racking Roll Forming Machine is for

producing the storage rack for workshop. It can uncoil, level,

punch and continuously roll forming with automatic cutting to

length. It is the essential equipment in the steel structure

industry.

The machine can be customized based on the customer’s specific

technical requirements.

Profile drawing (the profile can be especially designed according

to customer)

Work flow

Uncoiling→ Leveling→ Head cutting and welding→ Servo feeding→

Punching→ Roll forming→ Straightening device→ Post cutting→ Run out

table

High Quality Rolling Storage Rack Machine

| Detail Elements of the P beam rolling Machine | | No. | Name | Unit | Quantity | Remark | | Part 1 | 3 Ton manual decoiler | set | 1 | Hydraulic | | Part 2 | Main Machine with spot welding | set | 3 | Cr12MoV quench treatment | | Part 3 | PLC control station | set | 1 | Delta as default | | Part 4 | Disk Shearing | set | 1 | 15 Meter | | Part 5 | Hydraulic station | set | 1 | Hydraulic | | Part 6 | Spare Parts | set | 1 | |

|

| The work flow for P beam rolling Machine |

Decoiler- feeding- leveling - roll forming- - welding- cutting-

receiving table.

|

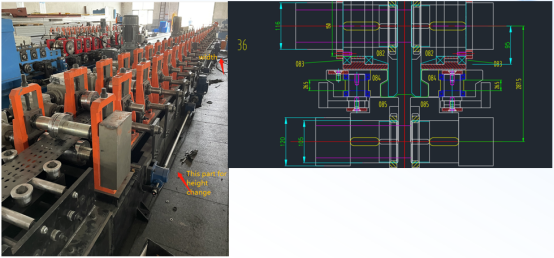

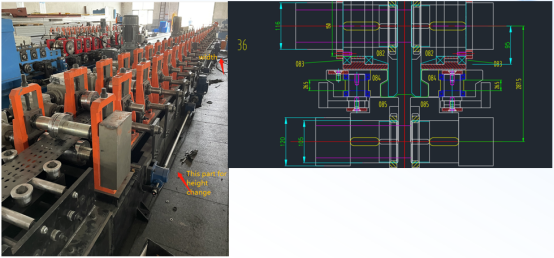

Upright Machine Design

1. If you have single sizes to make, we have fixed type upright

rolling forming machine.

2. If you want to make many sizes, we can recommend the fully

automatic type with the size changing.

Decoiler

You can choose manual one or hydraulic one.

Punching Options

For the punching part, you can choose normal brand punching

machine, or world famous brand punching machine.

Note: if we use bigger one, it will be faster and more durable.

About the rolling forming machine

For the machine design, we have the following types for your

reference Gearbox type :

Moldiing frame with gearbox type and with water cooling system.

More faster and more durable

Moding frame with chain

If you choose to use gear transmission, we only can use pillar

frame. If we use molding frame and then we have to use the chain

transmission. Compared with pillar frame, molding frame more

stronger.

As to the shearing part.

As to the shearing part, we can the servo tracking shearing. But as

the punching speed is not so high, even if we use servo tracking,

the speed also can not be too high. Max around 10 to 15 meter per

minute.

Mainly hydraulic sheairng. When shearing, it will consider the

holes, there will be no half holes cutting.

The working principle is far infrared shearing

When automatic size changing means

Automatic sizes changing means when you want to make many sizes,

when width or height changes.

We can make it by PLC control. But you need to change the cutting

baldes.

Receiving table

For the receiving table,you can choose the manual one, or you can

choose the automatic one.