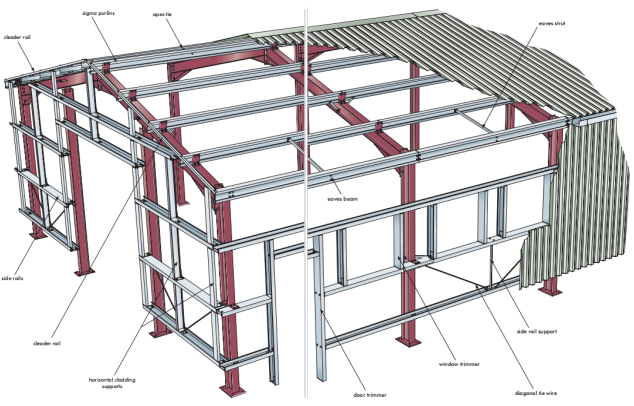

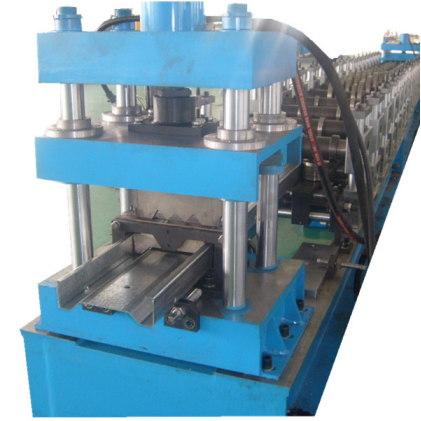

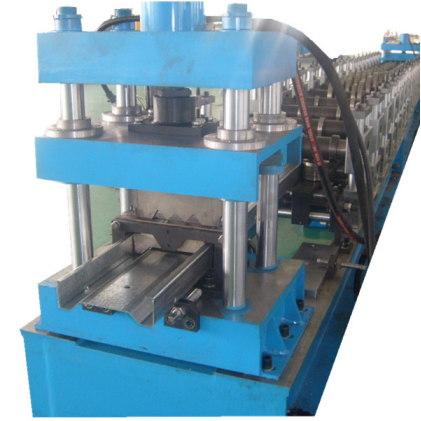

Sigma Purlin System Roll Forming Machine

It offers solutions from 120mm to 400mm with gauges from 1.2mm to

3.2mm, all fully supported by Strucad and Tekla Structures

detailing packages, which also generate

Cam Data to reduce the risk of potential errors, and remove the

need for the time consuming creation of drawings.

Our new Sigma Beam Purlin generates excellent strength to weight

ratio improvements, not to mention the reduction of accessory

requirements in common design criteria, saving the additional cost

of components and erection time on site. This product has been

launched using S450 material rather than the existing industry

standard S390, and the Sigma Beam Purlin used with our standard

range of C sections as side rails offers practical, flexible and

economical solutions for all your purlin and rail needs.

Product Range

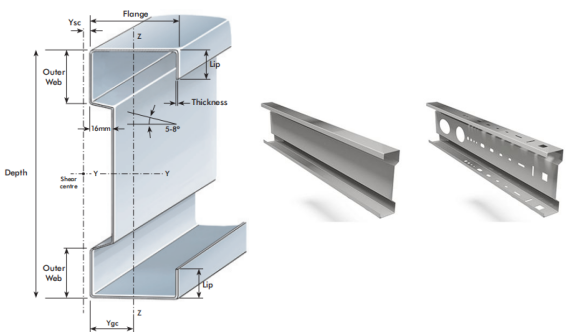

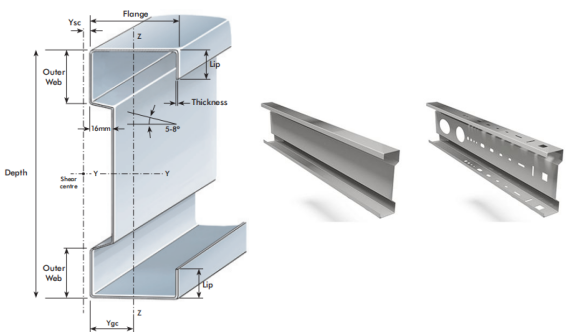

Here is a profile for your reference:

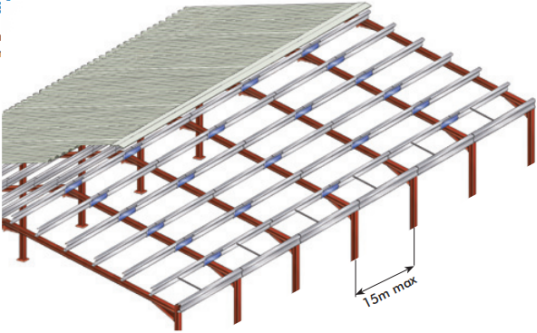

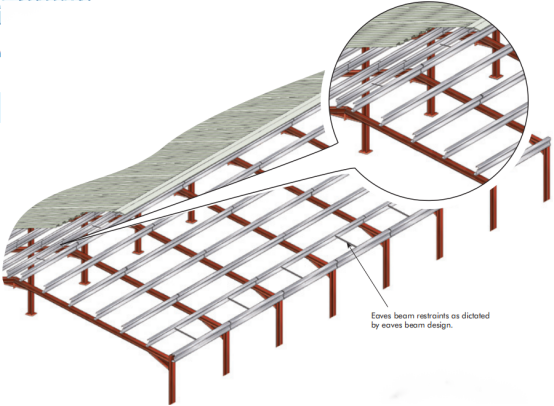

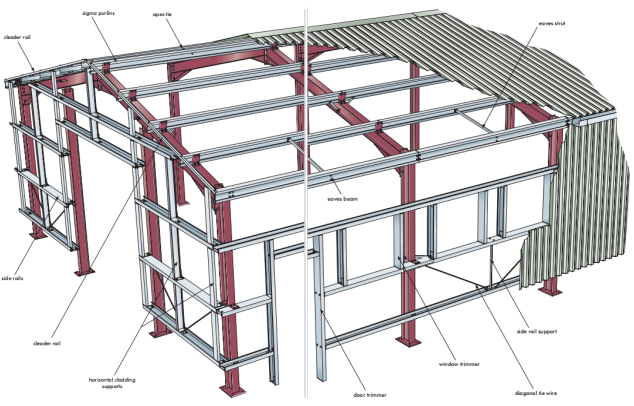

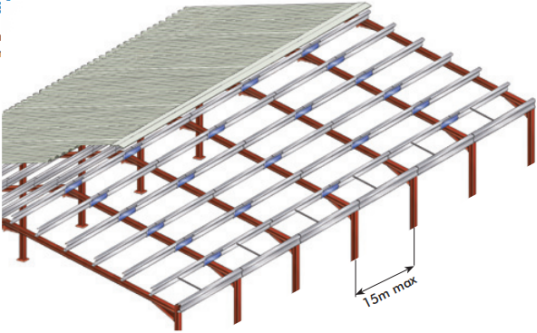

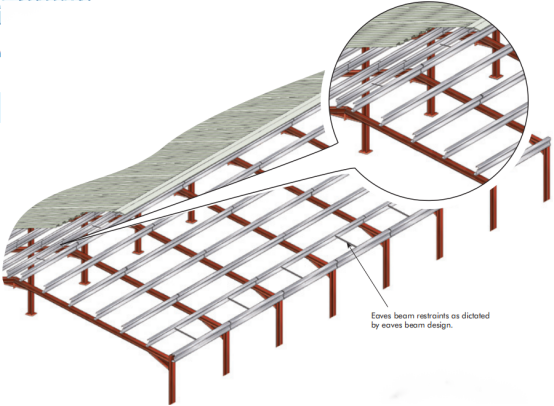

The system is designed primarily for use, on roofs, as secondary

sheeting support. Bay widths up to 15m and maximum roof slope of 25

degrees.Sigma sections are manufactured by cold roll forming

pre-hot dipped galvanised steel, grade S450, having a minimum yield

stress of 450N/mm2 Section properties have been calculated in

accordance with Eurocode 3, BS EN 1993-1-3:2006. Calculation of

ultimate loads and working deflections are based on the results of

full scale testing and finite element analysis. The top flange of

the purlin must have adequate restraint provided by robust steel

sheeting (or similar) fixed directly to the top flange. The steel

has an external galvanised coating Z275, giving an approximate

coating thickness of 20 microns each side.

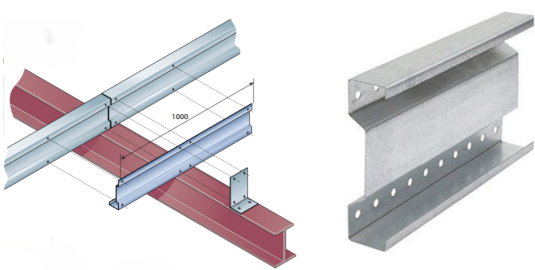

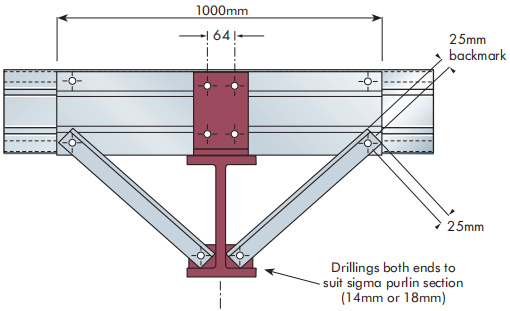

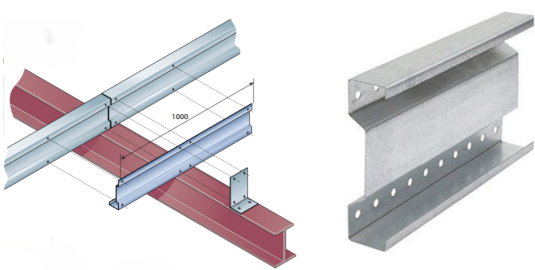

Sleeve Assembly and Cleat Details

Sleeves are required to provide structural continuity of the purlin

section across the supporting rafter. All sleeves are of similar

length and longitudinal drillings consistent. Sleeve thickness is

dependent on purlin thickness - see table.

The most cost effective purlin system, in terms of material content

and number of components to erect, is the double span butt system.

Purlin Cleat Details

Standard Sleeve Dimensions

Note: Where Albion standard cleats are not provided, take care to

ensure that sufficient clearance is provided from the underside of

the purlin to the top of the rafter for the installation of the

sleeve.

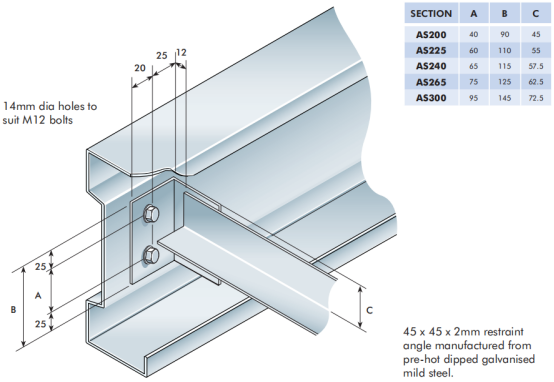

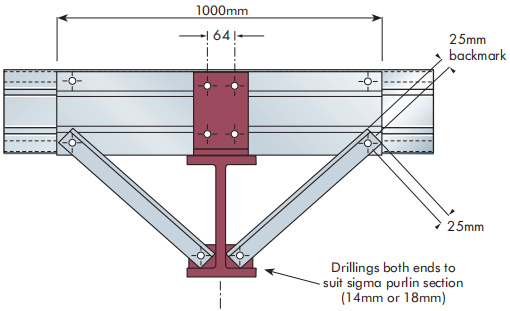

Sigma Standard Drillings

Standard drillings are shown below for the sigma purlin range.14mm

diameter sleeve and cleat connection holes, to suit M12 bolts, are

used for the 200, 225 and 240 series sigma, whilst 18mm

diameter, for M16 bolts, are used for the 265 and 300 deep sigmas.

All connecting bolts to be grade 8.8. Speed fix holes, where

required, are 14mm wide * 20mm rectangular. Holes to suit

intermediate span angle struts are 14mm diameter for M12 grade 4.6

bolts. 14mm diameter flange holes provided if required. Maximum

section length 16m.

Sigma Purlin System Roll Forming Machine

Sigma Purlin Systems and Joining Layouts

The sigma purlin shape provides an efficient, robust profile that

suits both short and long span conditions. In most cases of popular

building type sag rods are not required (subject to wind uplift

conditions).Sleeves are required to provide continuity to the

purlin section across the supporting rafters. The most popular

system, double spanning, has been specifically developed to

minimise the number of sleeves, thus reducing the number of

components and resulting in savings in installation time and

component cost. The sleeve details have also been considered in

terms of simplicity and duplication. All sleeves are the same

length with identical longitudinal dimensions, uniformity reducing

the chance of errors.

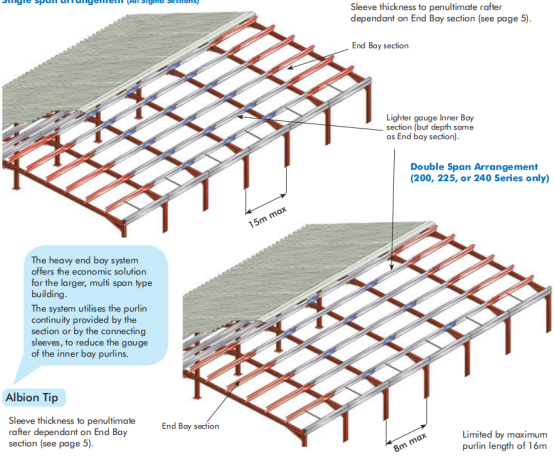

Single Span Butt System

The simplest of the purlin systems. Use where design conditions

dictate that no connecting sleeves can be used, i.e. purlin within

depth of rafter.

Double Span Butt System

Use with 200, 225, and 240 Series

The most popular purlin system combining double span lengths with a

minimum of jointing sleeves. The sleeved system can be used for

buildings with two bays or more and combines a cost effective

solution with ease of detailing. Bay widths are limited to 8m

(Maximum purlin lengths 16m)

Sigma Purlin Systems and Joining Layouts

Single Span Sleeved System

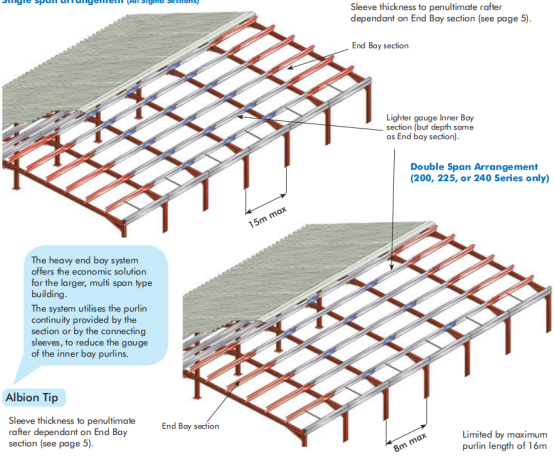

Heavy End Bay System An alternative to the double span system and

suitable for all bay sizes.May be used with all Sigma Sections.

Where purlins are required to be single spanning, but still

maintaining continuity over the rafters, the single span sleeved

system can be employed. With additional sleeves, as shown, the

ultimate capacities of the double span sleeve system can be

realised. Use also where access may be limited, i.e. purlin lifted

in from below.

Heavy End Bay System

Suitable on buildings of 5 bays or more Single span arrangement

(All Sigma Sections)

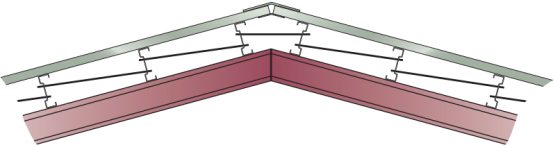

Speed Fix Anti-Sag Bars

Albion speed fix sag bars provide an effective restraint to the

purlin both during the cladding operation and under wind uplift

(reversal) conditions. The spring loaded clip fixing system makes

installation quick and easy. Speed fix should be fixed as shown

below

Anti-Sag bars serve two main purposes:

• To stop the purlin twisting during erection. (Once sheeting is

fixed the purlin derives a large measure of stiffness from the roof

membrane).

• To provide lateral restraint to the bottom flange under uplift

conditions.

Note:These details apply to roof slopes up to and including 25º. For

roof slopes greater than 25ºconsult our Technical Department.

Speed Fix are manufactured from 1.6mm thick pre-hot dipped

galvanised mild steel and cold formed into a channel section 15mm

deep * 12mm wide.Each end is notched to locate in the standard pre

punched rectangular holes at mid span or third points.Alternative

apex ties are manufactured from 12mm diameter allthread, zinc

plated finish.

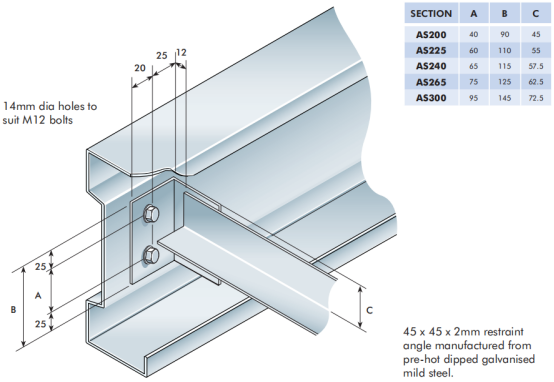

Angle Strut Purlin Restraints

For larger spans or deeper sections, angle struts are used to

provide stability during the cladding operation and under wind

reversal conditions. Angle struts are manufactured from 45*45*2mm

pre-hot dipped galvanised angle. Holes in the struts are all 14mm

diameter to suit M12 bolts.

Anti-Sag Minimum Requirements

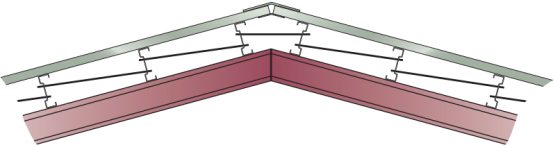

Apex ties must be used on all spans over 4m on duopitch roofs.

Long Roof Slopes

Where roof slope exceeds 20m, intermediate span restraint is

required to resist down slope loadings. This is provided by a strut

and tie system as shown.

Anti-Sag Minimum Requirements

Mono Pitch Roofs

On mono pitch roofs, strut and tie system is required at the apex,

to resist down slope loadings

Flat Roofs

(Slope less than 3º)

For very low pitch or flat roofs the Sigma purlins are installed in

facing pairs, as shown below Angle struts provided at mid span for

spans in excess of 4m and third span positions for span in excess

of 7.1m.

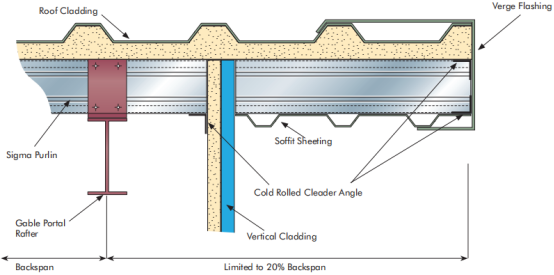

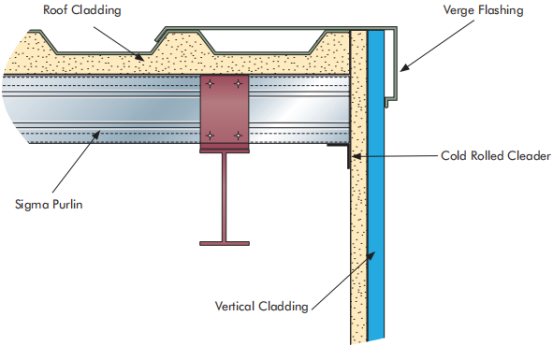

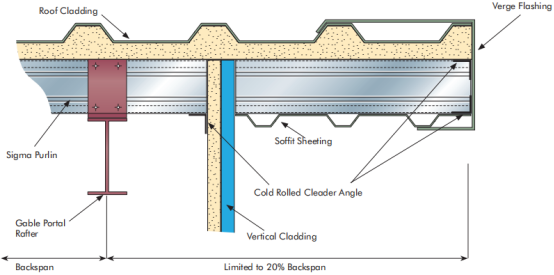

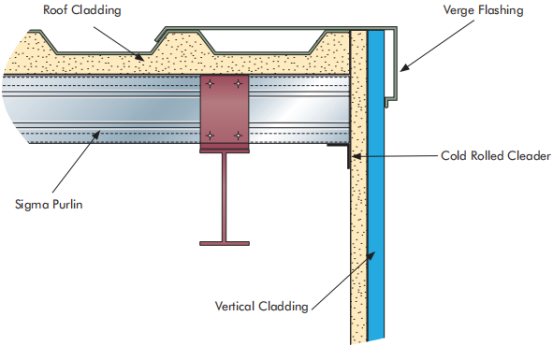

Cleader Angles & Rafter Stays

Rafter Stays/Column Stays

Rafter Stays are manufactured from pre-hot dipped galvanised mild

steel and cold roll formed into angle section 45mm x 45mm x 2.0mm

thickness.

Typical Details

Purlin Gable Overhang/Cantilever Detail

Gable Verge Detail

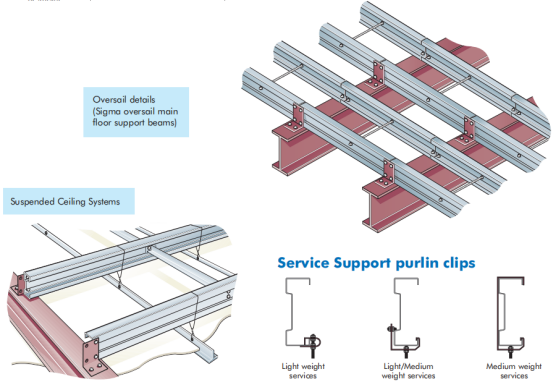

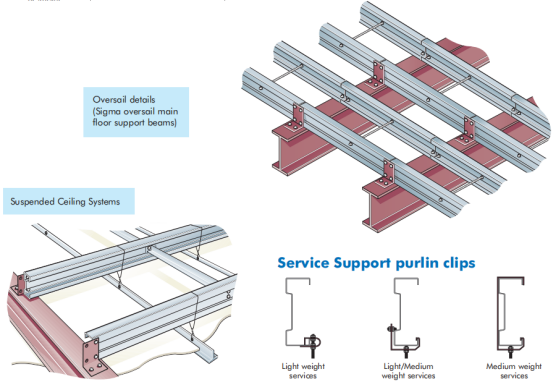

Further applications of Albion Sigma beams

Mezzanine Floors

The Sigma profile is ideally suited to provide structural support

to lightweight floors.

Sigma Purlin System Roll Forming Machine